Let’s Jump Right in by understand what is Industry 4.0

Industry 4.0, also known as the Fourth Industrial Revolution, refers to the next phase in the evolution of manufacturing and industrial systems — one that is driven by smart technology, connectivity, and data. It integrates digital and physical systems to create intelligent, automated, and responsive industrial environments.

Core Components of Industry 4.0

1. IoT (Internet of Things): Sensors and devices that collect real-time data.

2. Edge & Embedded AI: Intelligence embedded directly in machines to make real-time decisions at the edge.

3. Cloud & Digital Twins: Centralized systems to simulate, monitor, and optimize factory operations.

4. Automation & Robotics: Systems that self-adjust or respond dynamically.

5. Data Analytics & AI Models: Forecast failures, optimize quality, reduce downtime.

Industry 4.0 is closely related to AI and this is how

Artificial Intelligence enables

- Predictive Maintenance – AI analyzes sensor and machine data to detect faults before breakdowns occur.

- Process Optimization – Algorithms dynamically optimize manufacturing processes to reduce waste, energy use, and downtime.

- Quality Control – AI-powered vision systems inspect products in real time to detect defects.

- Autonomous Systems – Robots and AGVs (automated guided vehicles) make real-time decisions based on environment and task inputs.

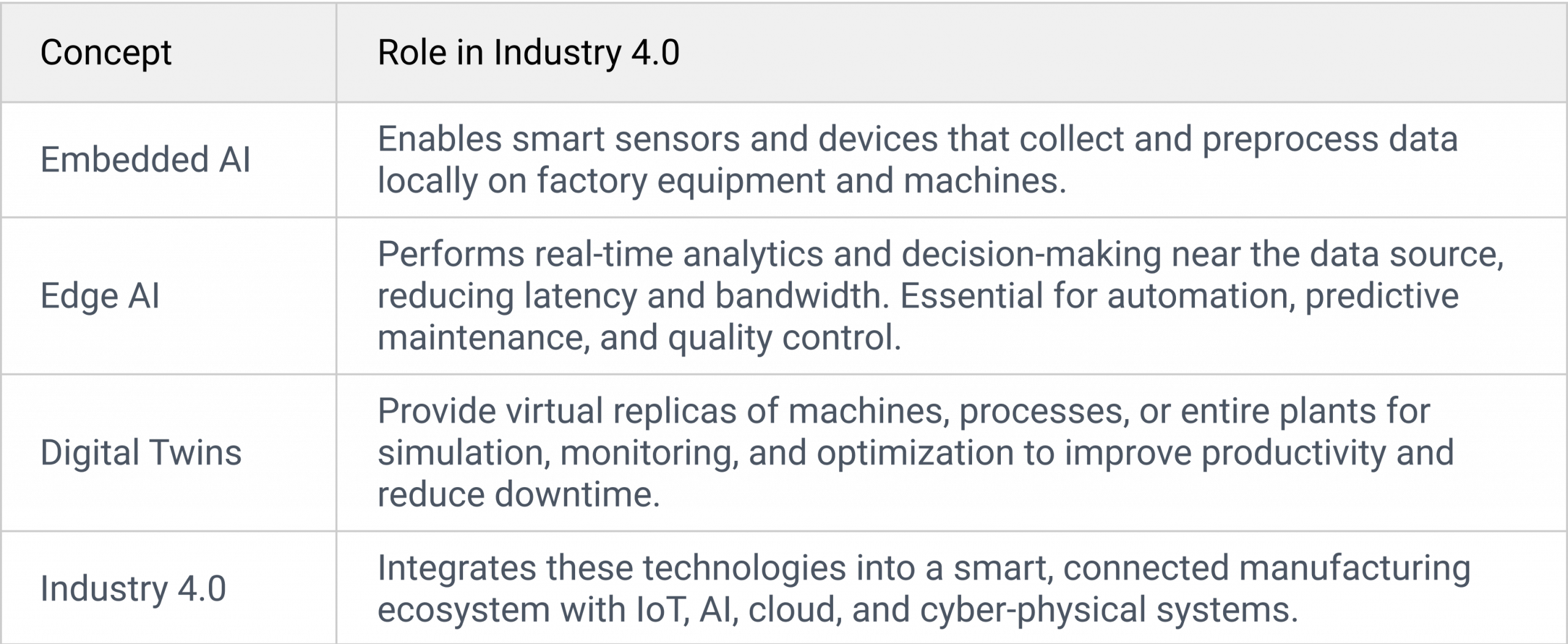

Industry 4.0 Embedded AI, Edge AI, and Digital Twins

Industry 4.0 closely integrates Embedded AI, Edge AI, and Digital Twins as core technologies

- Embedded AI runs on sensors and devices within machines, enabling real-time local data capture and preliminary processing.

- Edge AI processes and analyzes data near the source (on-site), enabling fast decisions, reducing latency, and minimizing cloud dependency.

- Digital Twins create virtual models of physical assets or processes, continuously updated with real-time data from embedded and edge systems for monitoring, simulation, and optimization.

Together, these technologies form the backbone of Industry 4.0’s smart, connected, and automated manufacturing environments, improving efficiency, predictive maintenance, and flexibility.

Relationship between Industry 4.0 Embedded AI, Edge AI, and Digital Twins Overview

Hence Industry 4.0 leverages Embedded and Edge AI for intelligent data processing and control at the device and local network levels. Digital twins are central for modeling and optimizing industrial processes in Industry 4.0. Together, using Embedded and Edge AI it enables automation, predictive maintenance, flexibility, and efficiency in manufacturing.

Now let’s see how Edge Impulse and Azure IOT work together to create an Industry 4.0 solution

Edge Impulse Embedded AI devices work with Azure IOT, including Azure IoT Hub, Azure Functions, and Azure Digital Twins, through standard integration patterns.

How Edge Impluse and Azure IOT Solutions Work Together

1. Model Deployment on Device: Edge Impulse helps train and deploy ML models on microcontrollers or edge devices (e.g., STM32, Arduino, Nordic, Raspberry Pi).

2. Data Output from Device: The model output predictions e.g., anomaly score, classification label. This data using standard protocols such as MQTT, HTTPS, or AMQP.

3. Integration with Azure IoT Hub: The device sends inference results to Azure IoT Hub using MQTT or HTTPS. IoT Hub then routes the data to services like

- Azure Digital Twins for visualization

- Azure Functions for automation

- Azure Storage for logging

- Azure Stream Analytics for real-time alerts

4. Security: Device identity, access control, and message signing are handled using Azure IoT SDKs.

Example Workflow

A vibration sensor with an Edge Impulse model running on STM32 detects an anomaly. It sends the result to Azure IoT Hub, which updates a Digital Twin and triggers an Azure Function to send a repair alert.

Azure IoT Hub is a backbone to securely and efficiently connect embedded/edge devices to the cloud, making it essential for scalable Industry 4.0 solutions.

1. An Embedded AI device detects vibration anomaly.

2. Sends alert + metadata to IoT Hub.

3. IoT Hub routes data to

- Azure Digital Twins (for visualization)

- Azure Functions (to trigger maintenance ticket)

- Azure Data Lake (for historical storage)

Strategy to build a Industry 4.0 with Edge Impulse and Azure

- Use Edge Impulse to develop and deploy efficient embedded AI models.

- Integrate the output into Azure IoT Hub and analytics stack for cloud-level insights, visualization, and automation.

Raydient Systems brings over 10 years of embedded product development experience along with deep AI expertise to bring Industry 4.0 solutions using Embedded AI such as Edge Impulse and Industry 4.0 solutions like Microsoft Azure IoT + Digital Twins.