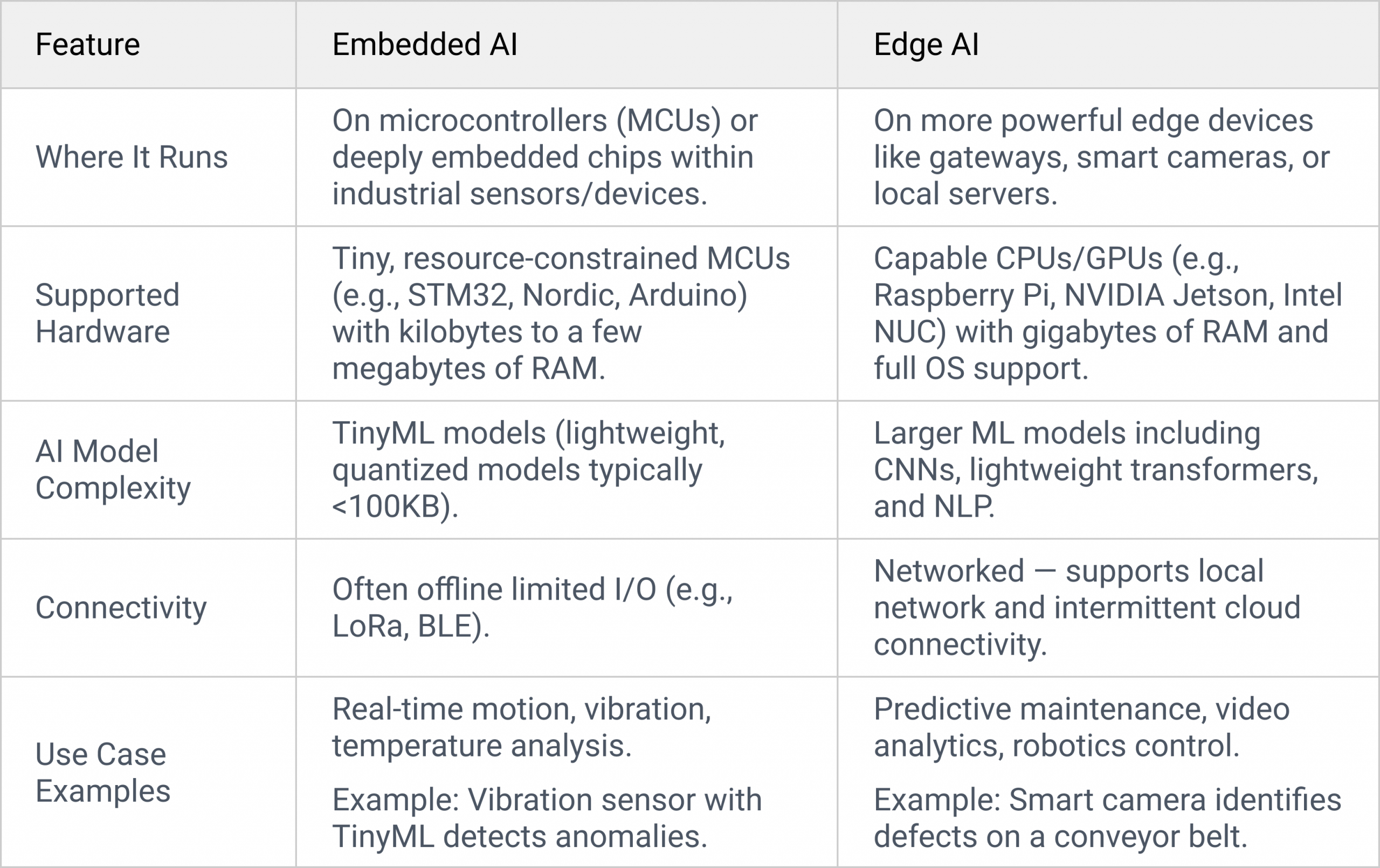

Edge AI and Embedded AI are closely related but operate at different layers of intelligent systems. Here’s a breakdown of how they are similar, how they differ, and how they work together—especially in the context of Industry 4.0.

What Edge AI and Embedded AI Have in Common

- Both perform AI computation locally—outside the cloud.

- Both enable real-time or near-real-time decision-making.

- Both reduce latency, bandwidth usage, and cloud dependency.

- Both can operate on physical devices near the data source (e.g., sensors, machines, gateways).

Key Differences between Edge AI and Embedded AI

How Edge AI and Embedded AI Work Together

- Embedded AI sits at the lowest level — within individual devices (e.g., sensors), performing localized intelligence such as anomaly detection or signal filtering.

- Edge AI aggregates data from multiple embedded devices and performs higher-level analytics, fusion, and decision-making.

- Both layers can communicate with the cloud for deeper analytics, reporting, or visualization — but only when necessary.

Step-by-Step Integration

- Embedded AI (Device-Level Intelligence)

- Runs on MCUs or embedded chips inside sensors.

- Handles first-level intelligence like:

- Simple pattern recognition

- Threshold alerting

- On-device anomaly detection

- Sends only summarized results (e.g., “anomaly_detected = true”) to edge device.

- Example: STM32-powered sensor detects irregular vibration patterns.

- Edge AI (Gateway-Level Intelligence)

- Resides on edge computing nodes like NVIDIA Jetson or industrial gateways.

- Collects input from multiple embedded devices.

- Performs complex analysis:

- Aggregation and filtering

- Real-time image/video inference

- Root-cause diagnostics

- Local automation (e.g., shutting down machines)

- Sends actionable insights or summaries to the cloud.

- Example: Gateway receives alerts from sensors and runs a diagnostic model to trigger predictive maintenance.

- Cloud AI Such as Azure IOT (Optional but Vital in Industry 4.0)

- Used for:

- Historical data analysis

- Predictive modeling

- Enterprise-level dashboards, alerts, and optimization

- Powers Digital Twin platforms like Azure Digital Twins.

- Example: Cloud AI monitors and visualizes factory status, maintenance cycles, and performance KPIs.

Real-World Example in Industry 4.0

- Embedded AI on a vibration sensor flags an anomaly.

- Edge AI on a Raspberry Pi aggregates multiple readings and confirms the need for maintenance.

- Cloud AI logs the event to Azure IoT Hub and updates a digital twin model.

Why Combining Embedded AI and Edge AI is Powerful

- Reduced latency: Faster decisions close to the action.

- Optimized bandwidth: Only filtered or significant data reaches the cloud.

- High resilience: Local AI continues working even when disconnected from the cloud.

- Scalability: Thousands of embedded nodes can connect to a few edge gateways.

This architecture supports the Industry 4.0 vision—where digital, AI-powered, and connected systems make industries smarter, faster, and more autonomous.

About ReliqAI

ReliqAI brings over 20 years of embedded product development expertise, combined with deep AI know-how, to deliver scalable Industry 4.0 solutions. We leverage leading platforms like Edge Impulse, TensorFlow Lite, and Microsoft Azure IoT to design and deploy AI-driven embedded and edge systems that are intelligent, connected, and production-ready.

Keywords for SEO: Edge AI, Embedded AI, TinyML, Industry 4.0, Edge Computing, Smart Sensors, AI in Manufacturing, Digital Twins, IoT Gateway, Predictive Maintenance, AI at the Edge, Industrial AI